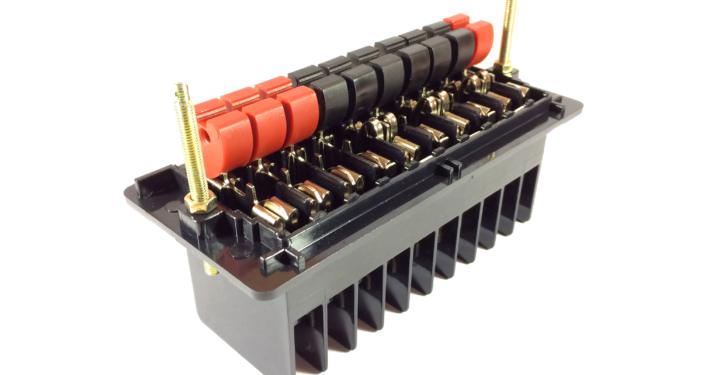

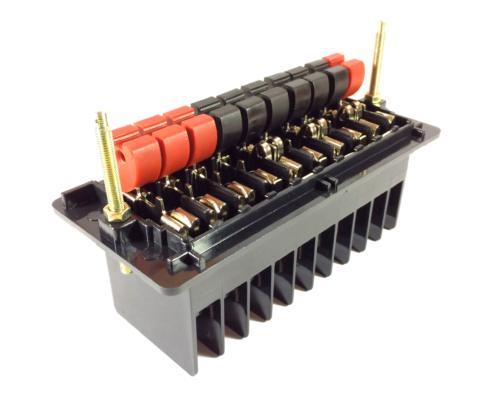

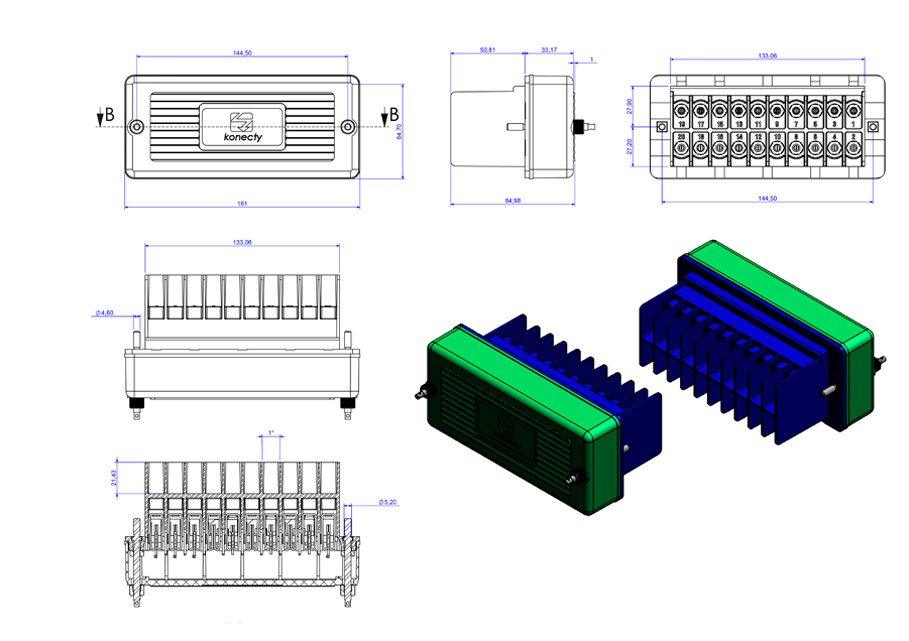

Semiflush-Mounted Test Switch 10 Poles KEY-E

The Konecty test switches have been developed according to the strictest security standards within the electric sector, designed to enable total security for the operators of electrical panels.

This being the simplest, quickest and most reliable way of performing tests, calibration and general monitoring of electrical equipment, without any need to de-energise the systems, we can therefore conduct potential and current tests on relays and energy measuring devices, among other industrial applications.

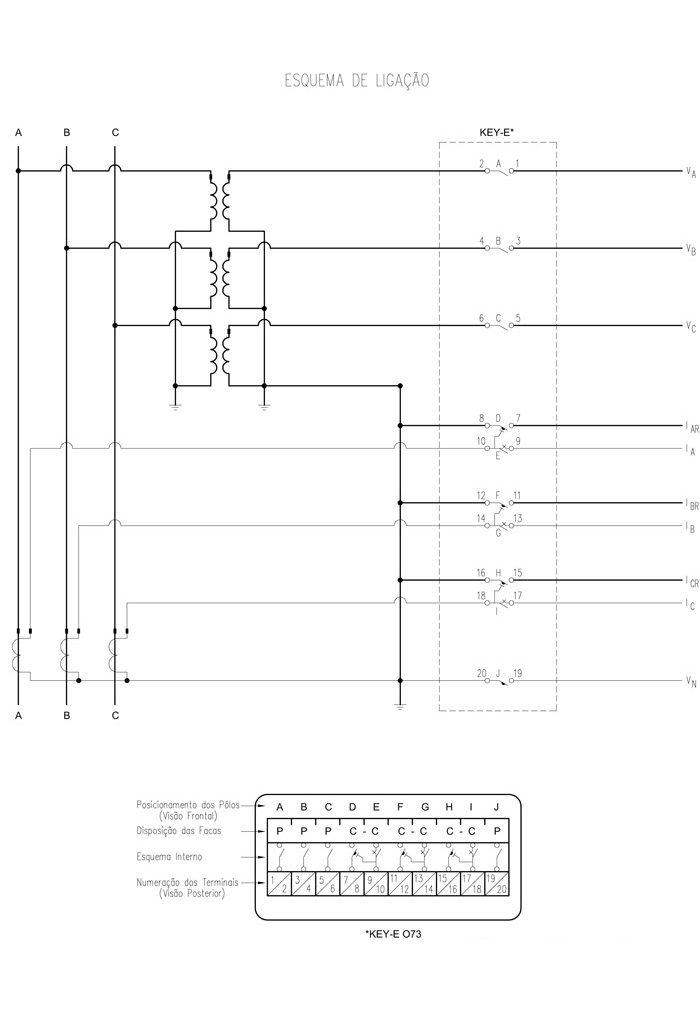

Configuration table

Technical Characteristics

- Manufacturer

- Model

- Nominal Voltage

- Assembly

- Nominal Current

- Insulation Class

- Maximum Number of Poles

- Konecty

- Key-E

- 600 V

- Semiflush-Mounted

- 20 / 30A

- 2,5 kV

- 10

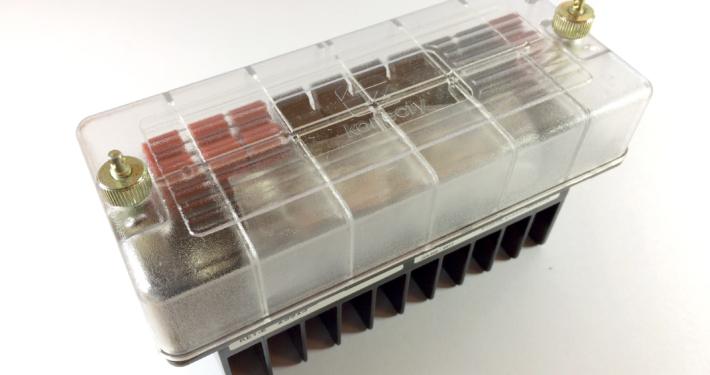

Optional

- Test springs for using test combs;

- Different colors for the keys;

- Transparent cover;

- Interlocking pins;

- Different mounting kits.

Total safety for electrical panel operators

When using the KEY-E switch, all test and inspection operations are carried out from the front of the panel, avoiding contact between operators and energized parts of the system.

The terminals are located at the rear of the switch, separated by barriers with a high degree of insulation and with adequate space for connecting the wiring.

Protection and Practicality

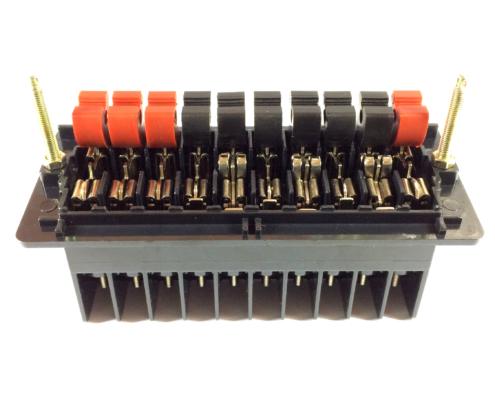

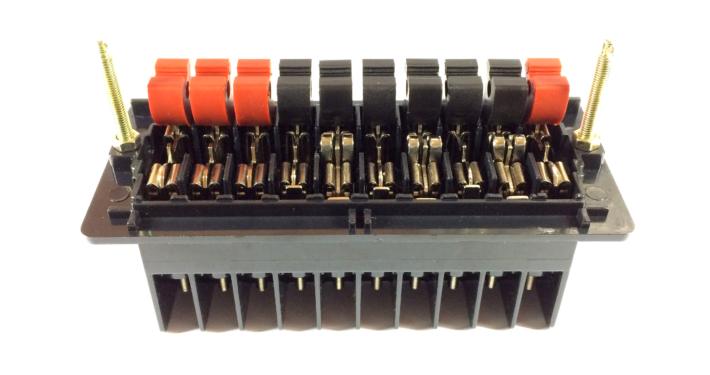

The switches are individual of the blade type and are separated by insulating barriers moulded at the base. Each blade switch has a handle, injected in highly resistant material (they can be coloured, with circuit identifiers and mechanical interlocking bars) which protects the operator from touching the conductive parts on its activation.

Construction features

Base

Injected in plastic material with excellent insulation and mechanical resistance, being able to withstand high temperatures without deformations in its structure.

Main Cover

Injected in plastic material with high resistance against mechanical shocks, available in black or transparent versions. The cover is removable and has sealing devices against fraud. Designed to protect the contacts, it has integrated closing nuts providing more safety and agility to the operator. It has indelible manufacturer identification.

Voltage and current sectioning assemblies

All sectioning assemblies are manufactured in special high-resistance brass, ensuring firm actuation and perfect contacts. Components with spring effect are manufactured in brass with molecular orientation, which improves flexibility and ensures long durability. In addition, all components undergo nickel surface treatment which, besides excellent finishing, provides smooth and sliding surfaces, as well as protection against wear and corrosion.

The voltage sectioning assemblies are composed of simple blade switches and have independent actuation for potential circuits. They are separated by insulating barriers molded in the base to avoid any possibility of voltage arcs.

The current sectioning assemblies are composed of double blade switches that allow short-circuiting of the current transformer secondaries before there is a total opening of the blade switches and circuits connected to the equipment/load. This way it is possible to isolate the equipment for conducting tests, maintenance and calibrations while keeping the CTs safely short-circuited.

Blade switch actuation keys

Injected in high-resistance insulating plastic material to protect operators from conductive parts. They are designed with a more ergonomic opening design and can be configured with different colors, circuit identifiers, and mechanical interlocking pins for opening two or more blade switches at the same time.